Do you ever think about how it is possible for factories to produce a wide variety of items, within such quick timeframes? There's one major key factor for this and its name is CNC machines! CNC — Computer Numerical Control What makes these machines so different is that they are able to replicate the same object multiple times and exactly. This means factories can produce more things quicker so they are very productive!

So, what is it that makes CNC machines so unique and special? Most machines are usually made to be operated by a human; conversely, CNC creation is designed specifically for computers. It is an instruction set like program. It instructs the machine exactly what to do, where it has to move and how material will be cut or shaped. It was thanks to this smart design that CNCs could work faster and more precise as any human ever can.

You see CNC machines are exact because they do what the computer program tells 'em to请rbrakk Excel BladesThat pair nicely with precision cutting and shaping to a micro-size that is hard to achieve by hand. Plus, they can work with high-strength stuff like metal and plastic to produce intricate shapes that go in lots of common things. But it is the CNC which provides amazingly sophisticated output, like parts for cars or planes — and prosthetics to help people.

CNC Machines Have Altered The Way Things Are Made Long before the invention of CNC machines, producing products manually would take ages and need a great deal of precision. It also had a bigger chance of fudging up. Today, factory production can be done much more and faster than it was in the past with less errors due to purchasing of CNC machines. It saves a ton of money and results in more products that people want to purchase.

Behind are hours-long protocols that can sometimes even stretch for more than a week — when some factories do work open 24 hours per day, seven days of the entire week! Apparently, they are able to produce thousands of products every single day. For that reason, you are going to have the ability get things much faster and for so more cost-efficiently than that which used to be.

Using a CNC machine offers several benefits! The most significant of which is efficiency- time and cost-saving. Due to their high speed and continuous operation, they save a significant amount of time and could make more errors than there are now delayed in production. Which in turn allows factories to either save money or, more importantly for most companies out their Violating all sorts of Human Rights Legislation sell there crap cheaper as well.

Another great advantage of the CNC machines is that they produce materials uniformly. These machines are controlled by a computer program and will make the same cut and shape every time. The significance of this consistency is paramount in industries such as aerospace, because accurate parts are essential to safety and performance.

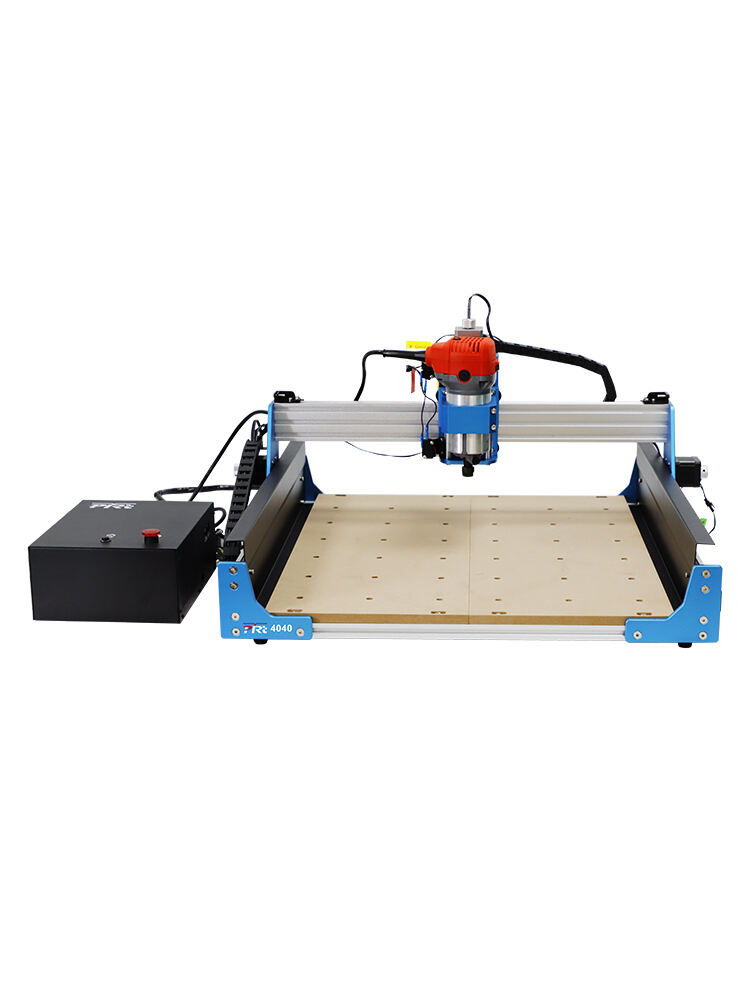

Being a leading CNC router machine manufacturer we have significant experience in exporting our services and products as well as service customization to allow for customer that is different We understand that customers could have specific requirements or operate in just a budget that is restricted and we're committed to providing solutions that meet their needs We have the expertise to style equipment that is efficient and attractive and still work within budgetary limitations A partnership is had by us with famous CNC brands such as cnc working VEVOR and Yorahome These partnerships help us increase our item offerings also to provide CNC that is superior router to our customers

PRTCNC cnc working operates from a building that houses four fully-equipped workshops ensuring production that is efficient We also have big organized warehouse with five floors for saving our massive inventory We can guarantee a fast shipping time and cut down the waiting time for the clients to get top-notch CNC machines the conventional delivery time for machines is generally speaking 5-7 days Machines developed to consumer specs are usually delivered within 15-30 days

We adhere to cnc working and controlled quality assurance procedures. Our unique production process involves the installation, testing, before disassembling and packing CNC router machines to ensure the highest quality of our products. From the selection of the raw materials through the testing and production phases We pay attention to detail. In addition, we offer an entire after-sales support system which provides 24/7, free technical assistance via email, Skype, phone, and TradeMessenger.

Foshan Puruite cnc working Co., Ltd (PRTCNC Factory) is a prestigious ODM OEM manufacturer specializing in CNC routers. Since the beginning of our existence in 2012, we have dedicated ourselves to the design, production and distribution of top-quality CNC Routers, along with maintenance services. Our self-production and self sales model will not only guarantee the availability of superior CNC routers but also allows customers to save their money.