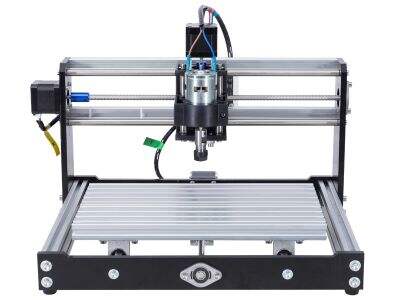

DIY CNC: A Revolutionary Tool for Your Projects

Have you ever wondered how factories create precise and detailed objects from raw materials? The PRTCNC answer lies in computer numerical control (CNC) machines which use digital commands to automate the manufacturing process. Thanks to innovation, you can have your own DIY CNC machine at home, which can help you create anything you need. Here are three things you need to know about DIY CNC:

Advantages of DIY CNC Machines

A DIY CNC machine has several benefits which make it an tool is appealing DIY enthusiasts and hobbyists. Firstly, it completes tasks rapidly and accurately when compared with machines that are traditional. Secondly, it is available, therefore you don't need to be an expert to make use of it. More over, it eliminates tasks which are repetitive can cause strains and fatigue in manual laborers. Finally, it's cost-effective over time since it requires less material wastage, minimal labor, and production is efficient.

Innovation in DIY CNC Technology

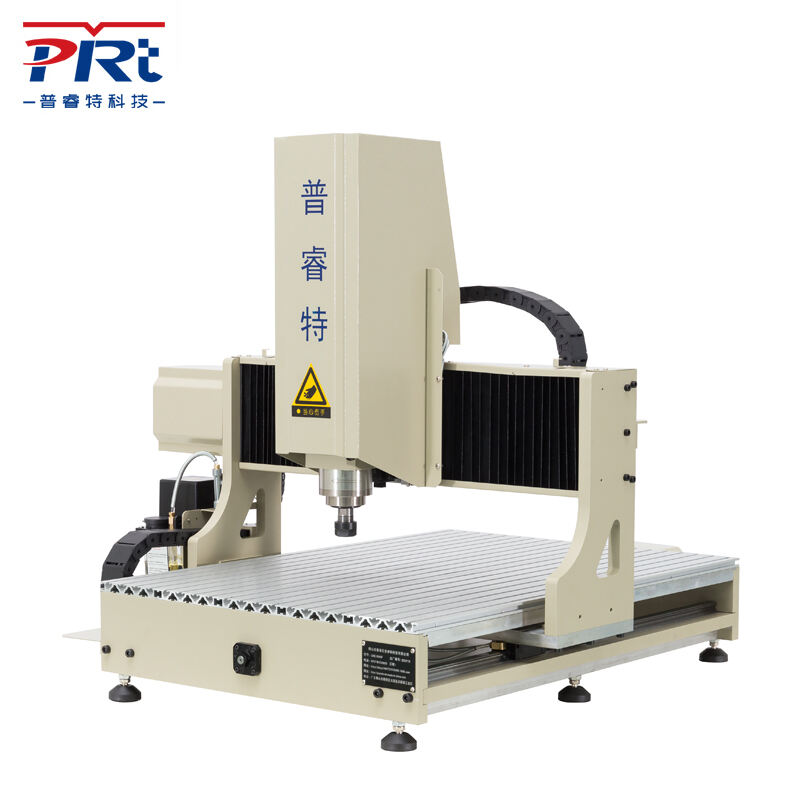

Innovation has transformed DIY CNC technology over the years. Today's machines are more user-friendly, cost-effective, and CNC Router versatile than their predecessors. New features, touch screens, plugins, and cloud connectivity, provide users more flexibility and control when creating their projects. DIY CNC machines also can accommodate materials which can be various plastic, metals, and wood, providing endless opportunities and designs.

Safety Precautions for Using DIY CNC Machines

DIY CNC machines aren't toys and may be utilized with caution to avoid injuries which are severe. Always wear personal equipment is protective as gloves, goggles, and ventilation masks whenever running the machine, especially when coping with sharp objects or dust. Make sure that you set up the machine correctly and stick to the manufacturer's instructions when using it. Disconnect the device from the charged power source when not being used to avoid accidents.

Just how to Use DIY CNC Machines

Using DIY CNC machines might appear daunting at first, but it is straightforward once the hang is got by you from it. Firstly, you need to design the item you need to make in a design is computer-aided CAD platform. After you have created your project, convert it into a file format recognized by your CNC is DIY machine. Next, you will need to load the style onto the CNC machine, secure the material to be machined, and turn on the machine. The device will move automatically as then per the guidelines in the file to generate any project.

DIY CNC Machine Service and Quality

When buying a DIY CNC machine, it is essential to buy from a maker is reputable can provide excellent service and quality. Choose a Woodworking machine that accompany a guarantee and after-sales support so that you can contact the company for help if you go through any issues. Check out the machine's reviews and ratings from other buyers to make sure that you get yourself a reliable and device is durable satisfies your preferences.

Applications of DIY CNC Machines

CNC woodworking router machines have range is wide of in various industries, such as woodworking, metalworking, 3D printing, and engraving. DIY CNC machines can make such a thing from furniture to jewelry, automotive parts to prototypes, and customize accessories. Furthermore, it can be used to replicate designs that are multiple high accuracy, which is vital for mass manufacturing and scaling.