電話ケースやネームプレート、サインなどの日常的な物体がどのようにして驚くべき複雑なデザインを手に入れるのか考えたことはありますか? 一部の人々は、これらの製品を作る方法の一つとして PRTCNC CNC彫刻機を使うことを知ったとき、驚くかもしれません。 このガイドでは、これらの機械がどのように動作し、シンプルなデザインを洗練された機能的な製品に変えるのかを教えます。

CNC彫刻プロセス

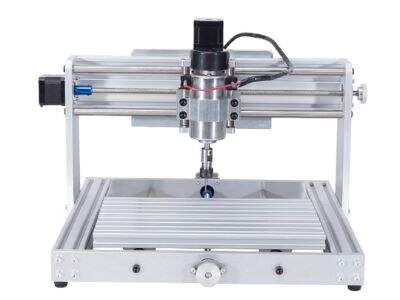

コンピュータ数値制御技術、または略してCNC彫刻機は、CNC彫刻機によって使用されます。この技術により、これらの機械は金属、プラスチック、木材、その他の素材を彫刻することができます。技術の進歩に伴い、CNC彫刻は伝統的な彫刻プロセスの代替手段となり、CNC彫刻の全プロセスには、高品質な製品を実現するために連携するいくつかの重要なステップが含まれます。

ステップバイステップガイド

ステップ1: デザイン

ステップ1: デザインを作成する(CNC彫刻の最初で最も重要なステップ)。デザイナーはCAD(コンピュータ支援設計)と呼ばれる種類のコンピュータソフトウェアを使用します。このソフトウェアにより、彼らは作りたい製品の完全なデザインを考え出すことができます。CADは、彫刻プロセスが始まる前にデザイナーが正確な寸法を得たり、最終製品の実際のイメージを視覚化したりできるようにします。

ステップ2: 材料

ステップ4: 製品に適した材料を選択します。使用する各材料は製品に異なる影響を与えます。材料の選択は、製品の強度、外観、コストに影響を与える可能性があります。例えば、金属のネームプレートはプラスチックよりも高価ですが、より長持ちするかもしれません。

ステップ3: プログラミング

材料が選ばれたら、設計をCNC機械のソフトウェアに変換する必要があります。ここでは、機械が彫刻を行う際の動きを管理するための特別なプログラムを作成します。このプログラムは、ツールの移動速度やカットの深さを指定します。このステップは、機械による設計の正確な彫刻を達成するために重要です。

ステップ4: セットアップ

最後に、機械をエングラビング用にセットアップする時です。CNC機械のテーブルには、材料が適切に固定されています。これにより、機械が動作中でも材料が動かないようにします。オペレーターはまた、エングラビングプロセスに使用される適切な工具も取り付けます。すべてが正しく設定されている必要がありますので、成功したエンgravd作品が得られます。

ステップ5: エングラビング

すべてが正しい位置に置かれた後、次にCNCを起動し、ついにエングラビングを開始できます。機械は先ほど構築されたプログラムに従って材料に切り込みます。オペレーターは、エングラビングが正常に処理されていることを確認するために、プロセス全体を通じて機械を監視します。これは、何か問題が発生した場合、損傷が広がる前に別のサービスがそれを検出する可能性が高いことを意味します。

ステップ6: 最終調整

彫刻が完了したら、オペレーターは機械から彫刻されたアイテムを外します。しかし、それが全ての終わりではありません。オペレーターは製品に対して最終チェックを行い、デザイン段階で指定されたすべての内容が正しいことを確認します。それがなぜこのCNC木材彫刻機が重要なのかです。これにより、最終製品が美しく機能するようになります。

デザインから製品まで

これらの機械で生産できる製品の範囲も非常に広いです。このプロセスは、一回限りのユニークなデザインを作成するために使用でき、大量生産にも対応できます。同じアイテムを一度に複数作ることができます。CNC彫刻機は非常に詳細で高精度の彫刻を生成でき、そのため複雑なデザインや精密なカットを手作業では不可能または非常に困難な場合でも実現できます。つまり、アーティストやメーカーは非常に美しいかつ驚くほど正確なデザインを生み出すことができるということです。

全体のプロセスを理解する

フルCNC木用彫刻ビットのプロセスにはいくつかの重要なステップがあり、最初のデザインから最終的な仕上げまで含まれます。CADソフトウェアはデザイナーが正確なデザインを制作するために必要です。デザインが作成されると、CAD/CAMソフトウェアがCNC機械にどのように彫刻中に削るかを正確に指示します。これは、オペレーターがすべてを準備し、適切に監督して精度と品質を確保する必要があります。彫刻が完了したら、最終製品が元のデザインと一致しているか確認されます。

その核心において、CNC彫刻機は製造業、広告業界、小売業を含む多くの産業にとって不可欠な機器です。CNC彫刻は、単純なアイデアを人々が愛する高品質な完成品にまで導く緻密なプロセスです。CNC彫刻機は信頼性が高く、正確で、ほぼあらゆる異なるプロジェクトにカスタマイズできるため、多くの種類の産業で使用可能です。