Ngokuqinisekisi, ungathanda ukwazi ukuba zinto ezikhoyo ezinikezeliyo njengezicase zomthumbe, amameko amagunya, kunye nezi-sign zingaphi izindlela zakhozo kuzobuyisela? Zikhawuleza ukubona ukuba umoya wabahlinzekile obunene kunye nesiqhelo esisetyenziselweni sasendawo. Lolu cwaningo lizofunyanwa ukuba le ncwadi ifanele yiya kuqala nokuba uqale ukusetyenziswa kwaye ungene kwi-design elibekwe ngokupheleleyo futhi ungene kwi-produkto engenayo uhlelo lokusebenza.

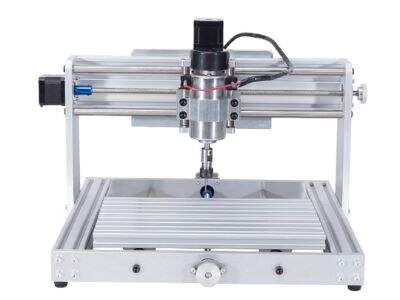

Iphrofesi ye-CNC Engraving

Umsebenzi wokubhala ngamandla yeehleni, noma i-cnc engraving machine njengezinto, usebenziswe ngemakhiya ye-CNC. Ngenxa yalento, izinhlelwa ziqinisekisa ukubhala amadela, amaphlasthiki, umphathi, kunye nezinye izinto. Ngokubanzi kuhluke kwentloko, u-CNC ubhaleka njengomthombo wesintsho sokubhala okulandelayo kunye nokuba yintlango yokubhala lwe-CNC ifakelwe imigomo ezininzi eziphumuleleyo ezifana nesinqumo sokuthola isiphelo esikhoyo.

Isithombe sentsha ngemva kweqhutywa

Imbizo 1: Ukukhangela

Imbizo 1: Yenza idilesi (imbizo yesonto sokuqala kunye nesilungiso somkhulu sokubhala kwe-CNC) Amadesayina zisetshenziswa inqwelo leendlu elijongwa nge-CAD, noma i-computer-aided design. Lwendlu lenqobo lingatshintsha ukuba ndizisisa idilesi emfaneleyo yeprodakhti oya kwenza. I-CAD ingatshintsha ukuba zibheka izimpondo ezikhoyo kunye nokubona umdlalo wenqanawe yenqanawa phambi kokusho kwe-CNC.

Imbizo 2: Izinto

Indlela yesiyo 4: Zama umthombo omphumeleyo wesiwo esisebenzayo. Ngumthombo wesintsho osusiwe kufuneka ashiwe ngendlela efanelekileyo. Ukusetha komthombo akuzange kube ngenxa yokuqinisekiswa, ukubonisa kunye nokuphuculeka kwesintsho. Ngokulandelayo, isithombe sometalu kungaphandle kwenziwayo kodwa kungabhedluleka kulula kakhulu kunye nephenethi.

Indlela yesiyo 3: Ukugcina

Ngemva kokuthi amathombo asebenzisiwe, isiqephu sifuna ukuba lisethwe kwindlela leprogram yeNCM. Lolu ncwadi lalayinqubo elizenzelwe ukubheka ngaphambili lokushintsha umakhiwo wenqanawe. Inqubo lingezima ngokukho umthombo uya kushintsha ngasiphi, kunye nokuhlola lokuhlola lokuhlola lokuhlola. Lendlala yiyo inceda ukuba usetyenziswa ngokuyenza ukushintsha kumbhali weNCM.

Indlela yesiyo 4: Ukusetsha

Ngemva kwezikhathi, kube ndawo ukusetshentela imakhi ethi CNC ukuze ubheka. Isitolo sesithelo samakhompyutha sibhekisele ngokuphumelelwe nehluko. Lokhu kuvumela ukuba ihluko asihambisane ngenqanawe lomsingisi wasekhethweni. Umncedisi wedwa yayingena isixhobo esetshenteleni kwiindlela yokubheka. Konke kufuneka kusetyenziswa ngokukhululekile ukuze usetyenziswa okanyeleyo umsebenzi wokuqinisekisa.

Iphakathi 5: Ukubheka

Uma konke kusetyenziswa ngendawo, sithumelela amandla komakhi ethi CNC kunye nokuba singenza into engeziyo. Imakhi ethi CNC ifolaka iprogramu yasetyenziswa ngaphambi kokuba siqinisekise hluko. Umncedisi wedwa yazingama imakhi ethi CNC ngentsimbi yonke ingxumbulo ukuba kusetyenziswa ngokukhululekile kunye nokuba umbiko wesixhobo wesetyenziswa wakwenzanga. Lokhu kuvumela ukuba uma kuhlangene nesintsi, umsebenzi omunye kungabizwa ngaphambi kokuba isiphumo sifunda.

Iphakathi 6: Amalungelo Akhonyene

Ngokushesha ukuvakasha, umsebenzi waphela uqhele amanxaso akho esivakalelwe kwi-mashini. Kodwa lokhu alingene ngenxa yokuba yonke into. Umsebenzi uqhele isicatshulwa sokugcina phantsi ngokubanzi kwisebe ukusureka ukuba yonke into ethunyelwe kusenqanawe sasentloko siya kuyinkcazo. Yonke le nto kunjalo lizizo lokuba le mashini ye-cnc wood engraving liyindlela. Liqinisekisa ukuba isicatshulwa esiphambili sibonakele kakhulu nesithetho esebenzayo.

Kwisentloko kwisebe

Izicathulo ezinikezelayo ezinezono zezityeleleyo ezinikamileyo ezinikezelwa ngamashini namandla. Leli ncamiso lingayibona ukuba kube ngokukhuthaza ukusetshenziswa ukwakhsa imibala engcono, okanye nokuphumula kwindawo elincinci, apho izinto ezifanekiso zizohlanganiswa ngemva kokucabanga. Iimashini ze-CNC zakuxhasa zakufuneka zikhuseleke amandla ngeengxenyeni ezidingekileyo, futhi ngokuba le ndlela, ziqinisekisa ukuba zidale imibala engcono ngeengxenyeni ezidingekileyo, into engaziqondisiweyo noma engaziphephethe kakhulu xa idinikelwa ngokushesha. Ukuthi lokhu lumendlululo ukuba amagqwaba nemasebenzi azibonele amandla apha amahle nokuba abe ngaphelele.

Ukufumana Ukuphatha Kwesikhatsi Sodwa

Kunezinye izindima ezikhoyo kulesikhatsi sokugcina amandla okanye ukubhukuda kwe-CNC, esihlanganisa nge-sayithi yakho yokusebenza kunye nokuhlola. Umsindo wase-CAD uhlola lokungcono kakhulu kwi-designers ukwenzela amandla akhona. Ngokusho lokusebenza lishintshwe, umsindo wase-CAD/CAM ulibizisa i-CNC machine ukuba bheka ngaphambili kuphela ukuthi kuya kuhluke ngalokhu lokugcina kwi-process yokubhukuda. Lokunye kuyinto engazange uyisebenzele ukuba zikhwethwe kakhulu kunye nokubaleka ngakwesobizo ukusombulula ukungcono kunye nokungqinileyo. Ngemuva kokubhukuda kukhwethwa, iproduct eyafunywa yaziqhutywa ukuba ibe ngokuqinileyo njengokushintshwa.

Ngokwesintsha, iimakhiyi ye-CNC yehlukumeleyo ziqhutywa ngokuphambili kwiingxenye ezininzi zemigca phakathi kokuthiweyo, umsebenzi okanye ukuhlawulwa. Ukugcina nge-CNC nguqulelo elincane olunyekelwa kusukela kwenqanawe kuphenetyana nokuba kusuke kulandelayo iprojekthi engazange abantu bayahlulekileyo. Iimakhiyi ye-CNC yehlukumeleyo zibhedlisekile, zikhethelileyo kunye nokuba zinikwe amandla ukubuyisela ngazo kwiinyanga eziningi ezidingeki, ngokubanzi bantakhi yiindawo ezininzi.