If you are planning for the woodworking business it is impossible to ignore wood carving routers as an option. A must-have in every woodworker's tool kit that help create intricate designs and shapes with ease. Whether you are a beginner just getting your feet wet in this amazing trade, or the seasoned veteran looking to better themselves and their work; I can assure that using one of these tools will change the way you see woodwork. This guide covers : The 10 best wood carving router methods perfect for novice users Pro tips to get a smooth cutting edge when using routers Best brands & models of carving-specific routers How to make intricate designs with your carver Creating advanced patterns with this tool And more!

For those beginners who are utilizing a router to get started with the wood carving journey, following is ten basic technique which will help you launch this learning process:

Learn Basic Cuts: First start cutting basic shapes - straight lines, curves and circles This guide will get you comfortable with the tool and also give you a taste of what it can do.

Apply Templates. Use templates as an easy way to transfer designs and edges on wood Pre-made templates or your own, both are essential for accuracy.

Precise Depth Adjustments: Set the depth of your router according to wood thickness and the kind of cut you want.

Speed Control: It is very important to keep the router on an appropriate speed so there are no errors or harm done in case of wood.

Secure with Clamps: Clamp the wood piece securely in place so it doesn't move around as you carve.

Safety First: Always wear the proper safety gear, such as protective silhouettes for working around a garage and ear protection.

Start Small: From simple beginner projects, gradually work your way up to more detailed designs.

After you have carved the walking stick now is time for to do some sanding and polishing.

Try Out Different Router BitsTest the waters of creativity by trying out different router bits to make unique shapes, designs and surface finishes.

Be Patient: Wood carving is a thing of patience. By rushing, minor errors are made; take the time for it to be done right.

Pro Hints to Get Perfect Carving Cuts with a Router

Follow these expert tips to achieve perfect carving cuts with a router:

Choose Sharp Bits: Using correct sharp bits for the wood type is important.

Follow Sequence: Every step is important, do not skip steps it all adds up to the final result.

Maintain Tool This means that you need to clean and refurbish your used router if the situation permits, so as not to reach its surpassing time.

Do not Apply Too Much Force: Allow the bit's sharpness, and speed do the cutting; there is no need to force down on the tool.

For Equilibrium: Use a surface pattern if necessary to have flat and prevent the router bit from over-cutting.

So many choices, so little time (and money) - how do you when it comes to choosing the best carving router? Some of the best brands and models include: A Guide to The Best Carving Router

DeWalt DW6182: With a powerful motor, variable speed and ergonomic handles for better comfort and control.

Bosch 1617EVSPK: Precise cutting with a kit that includes fixed and plunge bases in dual mode operations.

Makita RT0701CX7: A small form router suitable for little application jobs with a soft start, variable speed control and also an immersing base.

Product: Festool 574369 Designed for the serious woodworker, this design includes virtually no setup time and arrive to provide in challenging applications requiring a high level of precision.

Porter-Cable 7518 Router: A beast for heavy duty and larger projects, the auto-release motor switch features let you use it more efficiently on any project size.

It is a long journey that you will be taking in order to get started so begin creating your intricate designs with the help of a carving router requires patience, practice and following the correct methods. Here is a step by step guide to help you in this creative process:

Choose the Correct Template: The template you choose should be similar to what design do you want for your project.

Choose the right bit - there are so many choices to fit your project.

Practice: always practice cutting the wood on a scrap piece before starting your real project.

Depth Adjustment: Select the depth of your router bit according to how thick your design is.

Use the Guide: The guide will ensure accuracy if you strictly follow it and keep your hand steady while moving routers constantly.

Now a little finishing: Finish up by just doing some sanding on it, and getting your produce sanded properly And you can finish this clear specially if you are going to stain or color something.

To hone your carving skills and learn a little bit more about the uses of some router bits we already went over, here are advanced router techniques for seasoned woodworkers:

So Bring on the freehand carving: pay close attention to movements and magnificently own in designs without any templates.

Spiral Carving Try spiral carving, which uses a never-ending series of circular cuts to create stunning coiling designs.

Experiment with Replicate Carving: Make replicas of patterns using a bearing assisted little

Stencil Carving: Create a stencil design and use that to transfer the pattern onto wood, then you can go on using a router and carve out all those nooks.

Introduction to 3D Carving: Take your work into the third-dimension by using software that controls the router's movements.

Conclusion - Wood Carving Router Whether you are a beginner or an experienced crafter the physical instructions that adorn this source material will be invaluable should best carving cuts prove illusive as patterns become more complex and dexterity greatly needed influenced setPosition *assertSame(four, five) onBackPressed(Position(), Position()) Conclusion - A carving router, safety first and time-honored practice are your keys to wood carving mastery.

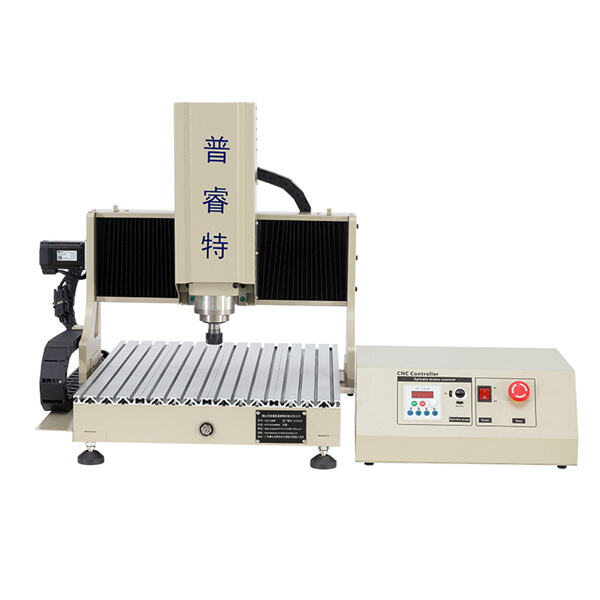

Foshan Puruite Technology Co., Ltd (carving router) is an esteemed ODM OEM manufacturer with a focus on CNC routers. We've been devoted to development, research production, sales, and maintenance service of high-quality CNC router machines since the beginning of our existence in 2012. Since 2012, when we first started we have been committed to the research, development and production of top-quality CNC router machines. We also offer maintenance services.

We're a carving router manufacturer with extensive expertise in exporting products also as tailoring services to meet a number of customer requirements We realize which our customers might have particular needs or work inside a budget that is tight and our company is dedicated to delivering solutions that match the needs of their customers Our expertise lets us produce machines with exceptional look and performance while working within budget constraints We partner with top CNC brands such as for instance Sainsmart VEVOR and Yorahome These partnerships help us to enhance our services and also to provide CNC that is superior router for our consumers

We adhere to strict and controlled quality assurance procedures. Our unique production method involves testing, installing, and then disassembling and packaging the CNC routers to ensure that the product is of top quality. From the choice of raw materials to the stages of production and testing We pay attention to the smallest of details. Additionally, we have a comprehensive after-sales system with 24 hour, no-cost technical assistance via email, Skype or carving router. TradeMessenger.

PRTCNC Factory carving router from a building that is home to four fully-equipped workshops ensuring efficient production processes In addition we have a large and well-organized five-story warehouse to store our massive inventory This allows us to provide fast shipment and shorten the wait time for our customers to receive our top-of-the-line CNC router machines The standard delivery time for machines is generally 5-7 days while machines built to customer specifications are usually delivered within 15-30 days