There is no doubt that CNC routers have changed the manufacturing and fabrication sphere as they offer unparalleled precision, speed, versatility. These machines are computer-controlled and can cut, sculpt or engrave a variety of materials with great accuracy making them invaluable tools in areas such as woodworking, sign-making, prototyping; even aerospace! CNC technology is becoming an increasingly popular topic and most everyone wants to know about the capabilities, uses and maintenance of CNC. In this Instructable, we will try to de-mystify the world of CNC Routers and explain some basic concepts for you based on review questions customers frequently ask us. By following along with these insights beginners can drill down into more detailed specifics when they are ready1 Step #3: Using a Small (but not too small) BitDepth also comes in numbers!

A Journey into Precision Cutting Tech

Did you ever wonder what is meant by CNC? CNC stands for Computer Numerical Control, which means that the machine tools are controlled by computer programming and not physical manipulation.

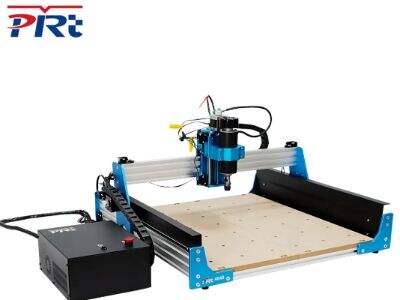

Enter the CNC router, and learn how one works after this. A CNC router basically used a spindle on an axis that moves around to machine the material in accordance with digital designs. These instructions are decoded by the computer, which tells each of these three motors (one per axis: X,Y,Z) how to move -- guiding a spindle along those axes in order to make precision cuts on material.

What Materials can a CNC Router Rout?

CNC routers are extremely versatile pieces of equipment, handling nearly any material that can be cut into or on. The most common materials CNC routers will shape include wood, plastics, composites aluminum foam and even certain steel types. The specifications of the tools and tooling also determine what materials a machine can effectively process.

Applications, starting from Woodworking to Sign Making and many more

CNC Routers in WoodworkingAs a woodworking tool, CNC routers are best for imparting detailed complexity to wood pieces including furniture components like intricate patterns and designs of cabinet doors as well as complex joints. These automated machines are designed to enhance operational efficiency and facilitate custom design opportunities.

In the sign making industry, CNC technology has exerted a deep influence in terms of how we make dimensional signs fro custom lettering and logos with materials including wood, metal, acrylic etc. This feature ensures uniformity in design and reduces production time by many folds.

It is also worth noting that the uses of CNC routers are not confined to those common applications. They find applications in a range of varied fields like architectural modeling, mold making for casting and automotive part production; even on the amenities side with sculpture or installation pieces.

How to choose the best CNC router bits for your project

The type of material, thickness and your final desired finish are just a few factors to consider when selecting router bits. Also, for future ventures, the horsepower of the router and how fast it operates should be in line with whatever bits you decide to go towards which will offer full compatibility.

There are many types of router bits all offering different cutting choices such as End Mills for general cuts through to V-bits used specifically when engraving, Ball Nose Bits perfect 3D shaping and for copy routing the Flush Trim Bit options. The thing is, every type has their specific function and it affects the end product of the project.

There are a lot of benefits that will come when you maintain your router bits. The lifetime of a bit comes down to things like how often it is used and the hardness of its material. Overall, they are successful in serving exfoliation; however maintenance is a must - ensuring you replace the cartridge when required and keep them sharp.

CNC Router is a Game-Changer of Investment for Scaling your Business

Before you buy a CNC router, it is important to consider your business needs and goals, the size/complexity of future projects, space constraints for housing this machine (they do take up some room), budget limitations and your plans for growing the business in the near future. Moreover, think about required training and software compatibility to guide your decision.

Introducing CNC routers to your business has the potential of increasing productivity and profit. These machines provide operational efficiency by automating processes, striving to eliminate errors and providing quicker turnaround times. This seems to also being the case in when it comes to providing tailored solutions that appeal more higher paying clients generating additional revenue streams.

When looking at financing options for purchasing a CNC routing machine, you would find that there are multiple manufacturers and dealers who offer payment plans similar to leasing or rent-to-own solutions. That is why these CNC technology are so important as they allow business on small and larger scales to grow healthy.

The Ultimate Guide To Maintaining Your CNC Router

Regular maintenance is necessary to keep your cnc router in top condition. Cleaning is performed, lubrication of moving parts, checks the belt and screw insurances proper spindle alignment. This, combined with calibration checks and software updates all add to how efficiently the machine runs.

Troubleshooting Tips for Common CNC Router Problems That Leads to Inaccurate Cuts Incorrect calibration, worn bits or software glitches can be problematic Referring to the very well written user manual, online forums or contacting technical support can help you greatly identify and fix these issues.

It is important to know when it is time for a professional CNC router service. Certified technician only for all of those difficult repairs like Electrical faults or big issues. Advanced repairs: Try to take on a do-it-yourself advanced fix without the proper expertise, and you could wind up voiding your warranty or even exacerbating whatever went wrong.

To put it succinctly, CNC routers are formidable machines that have forever altered the landscape of manufacturing and creativity. By learning in more depth about their use, the type of technology available to them, how they chose their tools for a particular purpose if there is investment potential involved when considering product development or maintenance; you can maximise what your customers are providing and take whatever project/business into orbit. Take advantage of the accuracy and flexibility CNC technology affords, and see for yourself what it can do to give you an edge in creating final products.