Round Rail Guides & Square Linear Motion System drums Two common types of linear motion systems that are referenced by engineers Though the systems work in harmony to make things appear sound and true on paper, both are a breed apart by virtue of their design as much as what they can handle.

Design and Construction

How these guides are laid out first. The round rail guides: These are straight cylindrical shafts - long length of circular bars that e typically made from steel. These may also have blocks with balls in them, linked by shafts. The balls help to minimize the friction while rolling on a rail. Square linear guides, on the other hand have rails that resembles squares or rectangles. Coupled with a blocks that hold multiple small balls or rollers. The square running rail design is responsible for increasing the contact area between block and rail, making it capable of supporting heavier loads while retaining rigidity.

Load-bearing Capacities

Most people can relate Square Linear Guides with weight handling heavy weights. Their very large surface area provides greater compliance for weight charges, and they more evenly distribute incoming forces over a wide range. This assists them in raising very heavy stuff, with no twisting and keeping an precision. But then, round rail guides provide lifting but may not be the most rigid support for large heavy weights.

Accuracy and Rigidity

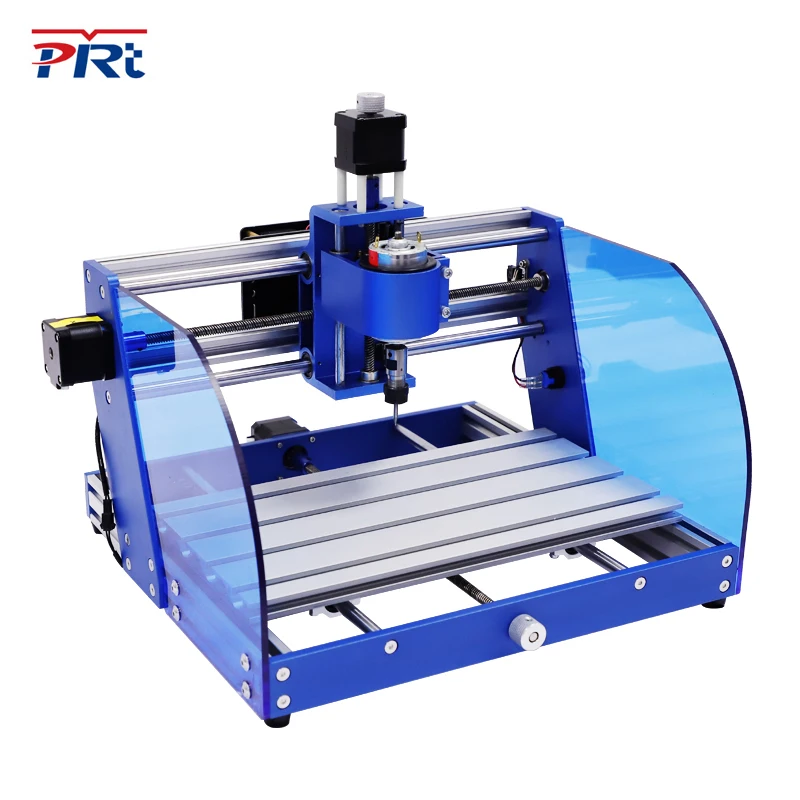

Square: one of the square types and it was used mainly tasks where a good precision/stability matters most, you could say... You're better off (and It'll save you lots of headache) do everything to avoid bending in first place but since that's not an option because its just made on a aluminum tube remember they have all been exposed once too some level bending/re-bending. For instance, they are suitable for use in CNC machines or robots that require a significant amount of precision. The round rail guides are less hardy to bending, as in they can bend more (although the new ones shim most of this out) and slightly inferior on stiffness compared with square rails but better accuracy which would normally only be used for ball screw applications that were looser like light duty automation/moving tables/or some sliding door mechanisms.

More System Guide Stuff

So, which one is better? So how do we know which data structure is right for our use case? If you require a proper heavy duty, extreme accuracey machine type system or high performance - then square linear guides are the ones youre after. If you just want to keep the machine minimal and on a budget, as long has round rails are ordered well they will be good enough.

What Apps Work Best with Circular and Square Guides

Which makes round rail guides ideal for things like furniture slides, conveyors and general purpose machine tools - but not much else where precision falls lower on the priority list. They also perform better in cleaner, moist or not-so-dirty environments due to simpler contaminants-protecting techniques. On the other hand, flat linear guides are perfect for applications in semiconductor production and medical equipment or aerospace technology with precision requirements. So too do machine tools, some types of automatic factory-assembly lines and precision measuring equipment.

Do right for your project

There are a number of considerations when it comes time to choose between round rail or square linear guides. At a minimum take into consideration the level of precision you need for positioning or alignment with your sensor data acquisition loops, along with how heavy what needs lifting/quickly things must move and dwell in between movements from one axis' operation to next step in sequence. And not to mention space constraints (how skinny it is where it goes) $$$ budget wise - all this, depending on these factors will have different ROI benefits kicking in for long hauls out into crazy town! From here, you can select the guide system that fits best for your project by considering all of these factors.

How to Make Maintenance Easier in Round Rail and Square Linear Bearings

For their second one of the day, it was a good idea for them to take care of guides so they last longer. Cleaning dirt and maintaining them off from round rail guide is easier to do because of their more simpler design. Their tracks are thus shielded against the ingress of dust and dirt, keeping them altogether cleaner than alternative square linear guides that employ a variety of sealing systems. Cascade linear way welk are square in shape instead of rouded, therefore they should be more reliable over time but square linear ways also mean less smmothness and higher maintenance regarding cleaning and lubrication. But then their cheekiness compensates for it on maintenance side so.... Make sure you select the appropriate guide system for your maintenance capabilities and where they will be employed in order to ensure maximum lifetime of operation.

In summary, round rails and square linear guides both aim to do the same thing (keep things moving straight), but each of them have their own unique strengths that make one more suitable for various uses than another. You should carefully consider what automation your project requires so you can best match them with features from various guidebock systems, in the end making an informed choice that is efficient and reliable as slides are known for.