Kutheni kungenjalo i-Diy CNC Router Build Guide UMGANGATHO OPHEZULU : Yonke indlu idinga enye yezi zixhobo ezimangalisayo Ulungelelwaniso < T > Lo MSHISHINI OMHLE UNAKWENZIWA, UQEQE kwaye UQHELE nayiphi na into efana ne-WOOD okanye i-PLASTIC ngokuchaneka okukhulu! Okungcono, unokwenza i-router ye-CNC kwizinto ezilulaAyiyo mali ingako. Yakha kunye nam!

Ukwenza eyakho i-router ye-CNC inokuba yinkqubo eninzi eyoyikisayo kwaye yanelisayo ngaxeshanye, Njengoko kusenzeka, idemokhrasi lishishini elinzima nelineenkcukacha ezintsonkothileyo. Yiprojekthi eyonwabisayo equlathe amanyathelo aphambili okuqhubeka nayo.

Yila uyilo lwakho ephepheni kwaye ubone ukuba yeyiphi isayizi yomatshini owufunayo ukuze udlule kwiingcango zawo. Nikela ngoncedo lwe-intanethi kunye neesoftware zasimahla Yakha uyilo olusisiseko lweCAD lomatshini wakho

Lungiselela IiMpahla : Ziquka iinjini zeStepper, iibheringi zelinear, iibhodi zolawulo ziqhuba iintonga kunye nezikrufu njl.

Ukuqulunqa: Nyusa iAluminiyam extrusions / iibhodi kwaye uyifakele umatshini wakho. Yenza isikwere, kwaye wenze ibe stout.

Ukunyuswa kwe-Electronics kubandakanya ibhodi enye yeKhompyutha, iMithetho yoMbane kunye nezinye iindawo zombane. Ukongeza, ii-motor stepper ziya kunikwa amandla ngebhodi yokulawula.

I-Spindle: I-Spindle isetyenziselwa ukubamba isixhobo sokusika apho inokuba sisisiki, i-drill okanye i-laser. Yongeza kwinqwelo ye-axis kunye nokudibanisa nemoto yethu yokuphotha.

Nje ukuba ukhululeke ngakumbi ngenkqubo yendibano, ndiyakukhuthaza ukuba ukhe ujonge kwaye ulungelelanise irhamncwa lakho ngenye yezi. Ungasebenzisa i-GRBL okanye i-Mach3 ukusebenzisa umatshini wakho kwaye wenze ikhowudi ye-g.

Njenge-CNC yokuzenzela, kumnini wekhaya ungajonga ukugcina iindleko ziphantsi kwezi ndawo njengawo nawuphi na umba wakho Yenza ngokwakho umatshini we-CNC. Iingcebiso eziluncedo zokonga imali kwezi Platform

Recycle Parts - bandakanya amacandelo asuka kwabanye abashicileli abanjalo okanye i scener ukugcina kwiindleko. Uqhawule ukuze uvune iibheringi zemigca, iimoto zenyathelo, iigiya, iibhanti njl.

Izinto ezixabiso liphantsi: Sebenzisa imiqadi yeplanga okanye imibhobho yePVC kwisakhelo endaweni yexabiso eliphezulu le-aluminiyam extrusions. Ngaphandle koko, unokuhlala usenza itafile engaphezulu kwi-MDF okanye i-plywood enobunzulu obuncinci ukuba kuyimfuneko ngenxa yezizathu zebhajethi.

Iindawo zokuthenga ze-Scour zentengiso kunye nezaphulelo-ezilandelwa yi-Amazon, i-ebay okanye i-Aliexpress Unokujonga kwakhona i-craiglist okanye uluhlu lwendawo lwesibini koomatshini be-CNC kunye namacandelo.

I-elektroniki ye-Homebrew: Ngexesha elizayo, endaweni yokuthenga iikiti ezixabisa kakhulu zakha ii-PCB zakho uxelela ihlabathi ukuba ukule ndawo yokukhwela isekethe yoKhozi okanye uyilo ngcono ngokwakho usebenzisa i-KiCAD. Ukufumana iinxalenye ezidityanisiweyo kwiivenkile ze-intanethi okanye abathengisi bendawo ngexabiso eliphantsi.

Ke ukuba ufuna i-router yakho ye-CNC ilungiselelwe njengeyona ifanelekileyo kwimfuno yomntu landela la manyathelo kwinyathelo ngenyathelo imiyalelo:

Iinjongo ezinqwenelekayo umntu kufuneka azilungiselele Phambi kokuthenga irutha ye-CNC: Ukuqhubela phambili ngenyathelo elikhulu, kufuneka uvume ukuba zeziphi iiNjongo ezinokuthi ishishini lakho liqhutywe ngesandla / uchwetheze ukuya kuthi ga? Ngaba ujonge ukusebenza ngomthi, isinyithi okanye i-polycarbonate? Ngaba ufuna iimpawu zakho, iithoyi okanye ifenitshala? Iinjongo ezicacileyo

Phuhlisa: Yenza uyilo lomatshini wakho ngesoftware yasimahla efana neSketchup, iFusion 360 okanye iSolidWorks. Okanye isakhelo, umphezulu wetafile, ukusonta ukugcina umsebenzi wakho ungashukumi kunye namasuntswana ombane.

Umthombo weZixhobo: Bhala uluhlu lwezinto zokwenza i-router ye-CNC ngokwakho. Thenga kwi-intanethi okanye kubathengisi bendawo Qinisekisa ukuba unezixhobo ezifunekayo kunye nemathiriyeli yokusebenza nazo.

Yakha uMatshini wakho: Hlanganisa umatshini ofanayo ochazwe kwicandelo lenkqubo leSikhokelo sokuSebenza. Hamba kancinane, ungahambi ngokukhawuleza kwaye ujonge ubungakanani.

Uvavanyo lweNdibano yePosi kunye noLungiso / ukuTyunwa Sebenzisa isoftware efana ne-CNCjs okanye i-Universal G-Code Sender ukuthetha ngakwimatshini wakho kwaye wenze ikhowudi ye-g (i-rotator ilinganisiwe, igqibelele?).

Kwabo bangaphandle banamava okusebenza ngamaplanga, i-DIY CNC router yokwakha ngokuqinisekileyo yenye yeeprojekthi eziguquguqukayo abanokuthi bangene kuzo. Stylisa umatshini wakho ovelise uyilo oluneenkcukacha, iipateni okanye ukusikwa okuhle kunye nemizobo / imizobo. Nazi ezinye zeeprojekthi onokusebenza kuzo nge-router yakho ye-CNC kodwa ziya kuhlala zinomdla kuwe.

Iimpawu: Yila iimpawu zakho zekhaya, umsebenzi okanye isitudiyo sobugcisa. Xuba kwaye utshatise kunye nezinto ezahlukeneyo ezibandakanya umthi, i-acrylic okanye isinyithi - ukulungelelanisa ngakumbi ngokubandakanya isicatshulwa kwi-sidewalls, iilogo ezifakwe ngaphakathi koyilo (i-Instagram pic ngokwayo), .. uyibize!

Kubantwana kunye nabantwana abaKhulu: ezi ziiToys ezenziwe ngezandla ezinokuthi zibhalwe njenge-Automated operation of multiple 3D shapes ezisetyenziselwa izidalwa ezithile ezifana nerobhothi, isilwanyana okanye ukwakhiwa kwesithuthi kusetyenziswa izinto zomthi ngokwazo.

Ukusetyenziswa kweFanitshala yeKhaya kunye neOfisi: Yongeza uchuku lwakho ekhaya okanye eofisini ngefanitshala elungiselelweyo. Iitafile zokhuni, iZitulo kunye neeshelufu zeNcwadi, ukwenza iMetal uyilo olulodwa

Ubugcisa-Inokujongeka icocekile kangakanani indawo yokugcina impahla ukuba ubunamaplanga amahle okanye amaqhekeza e-acrylic abekwe kufutshane negumbi lokuhlala, ifuna nje ukuthethelelwa ngokwendawo yakho kunye nezinto ozithandayo ngokunjalo. Guqula i-router yakho ye-CNC ukusuka kwi-abstract ukuya kwifoto yokwenyani ngokulula.

Nantsi indlela yokwakha enye ukusuka kwiingcali eziphezulu ze-DIY CNC router, kunye neengcebiso ezithile ukuba ucinga ngomatshini owakhiwe ekhaya.

Jonga ezi ngcebiso zeengcali kwaye uqalise ukwakha i-router ye-CNC eyakhelwe ekhaya ngemali encinci eya kuhlala. Yijonge inzima kwaye iyadinisa, Landela ezi mfihlo zixabisekileyo:

Funda Isifundo Sakho, Yenza Umsebenzi kwaye Chitha ixesha Ukuchaza iSicwangciso se-CNC NGAPHAMBI Kokwakha Ukuthengisa ngaphandle kweli nyathelo kubi xa uthatha iiodolo zefenitshala yeofisi. Iseti epheleleyo yamacandelo afunekayo kunye nesoftware, ifoto ye-anosymy_songa enye kwaye wonge ixesha.

Phuma nje apho kwaye u-DIY i-CNC Router yakho, ukuba umtsha kuyo kwisakhiwo se-CAD / CAM fumana into encinci, elula okanye esisiseko ekuqaleni. Kulungile! le ndlela iza kubancedisa kungekuphela nje kwimagi phezulu kodwa nokwenza ukuzithemba ukuze ifanele uphuculo lwesondlo.

Ukuchaneka kunye nokuzinza: Umatshini kufuneka uchaneke - uzinze. Oku kuya kukunceda ugcine isikwere sakho sesakhelo, inqanaba kwaye uzinzile macala onke ukuze ufumane iikopi ezifanayo ngalo lonke ixesha. Sebenzisa kuphela amacandelo akumgangatho ophezulu

Ukuhlanganisa Konke kunye ne-QC: Nje ukuba indibano yakhiwe kufuneka ivavanywe / ilinganiswe ngokubanzi. Lawula umatshini kwaye ufumane ikhowudi ye-g kwinto efana ne-CNCjs okanye i-Universal G-Code yomthumeli. Yenza umatshini ulinganiswe ngokufanelekileyo kwaye uhlala kumgangatho wonke.

Ngokulandela ezi zicwangciso ungasebenzisa i-CNC Router yakho kwiiprojekthi zeplanga ngokukhawuleza, ukuguqula iiyure zomntu kwiimveliso kwimbuyekezo engenakulinganiswa kutyalo-mali.

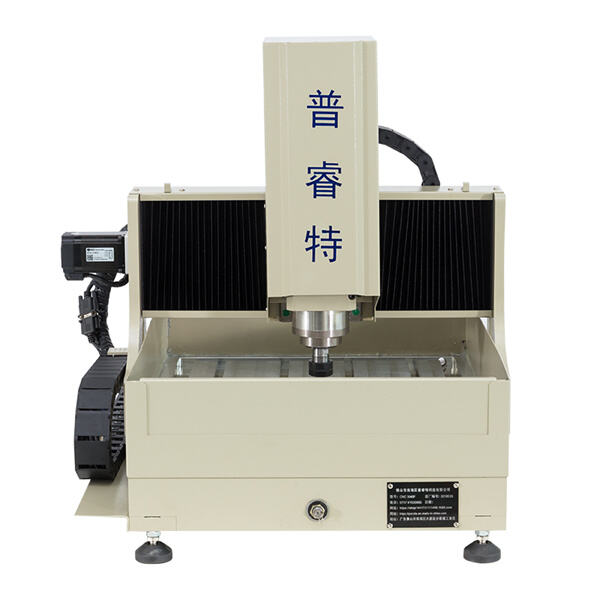

I-Foshan Puruite Technology Co., Ltd (i-PRTCNC Factory) ngumvelisi we-ODM OEM ohloniphekileyo okhethekileyo kwii-router ze-CNC. Ukususela ngo-2012, xa siseka inkampani sizibophelele ekudalweni, ukuveliswa kunye nokuhanjiswa kwee-router ze-CNC ezikumgangatho ophezulu, kunye neenkonzo zokulondoloza. Ukususela ngonyaka ka-2012 xa siqala ishishini lethu siye sazinikela kuphuhliso, uphando kunye nokuveliswa kwe-diy cnc router build ekumgangatho ophezulu. Sikwabonelela ngeenkonzo zokulungisa.

Sibambelela kwiinkqubo ezingqongqo nezilawulwayo zokuqinisekisa umgangatho. Indlela yethu ekhethekileyo yokuvelisa ibandakanya ukuvavanya, ukufaka, kunye nokuqhaqha kunye nokupakisha ii-router ze-CNC ukuqinisekisa ukuba imveliso ikumgangatho ophezulu. Ukususela ekukhethweni kwezinto eziluhlaza ukuya kwizigaba zokuvelisa kunye nokuvavanya Sibeka ingqalelo kwiinkcukacha ezincinci. Ukongeza, sinenkqubo ebanzi emva kokuthengisa ngeyure ye-24, akukho ndleko yoncedo lobugcisa nge-imeyile, i-Skype okanye i-diy cnc router build. TradeMessenger.

Singumenzi wokwakha we-diy cnc umzila onobuchule obubanzi ekuthumeleni iimveliso ngaphandle njengeenkonzo zokuthunga ukuhlangabezana nenani leemfuno zabathengi. Izisombululo ezihambelana neemfuno zabathengi babo Ubuchwephesha bethu busenza ukuba sivelise oomatshini abanenkangeleko ekhethekileyo kunye nokusebenza ngelixa sisebenza ngaphakathi kwemiqobo yohlahlo lwabiwo-mali Sisebenzisana neempawu eziphezulu ze-CNC ezifana nomzekelo iSainsmart VEVOR kunye neYorahome Ezi Intsebenziswano isinceda ukuba siphucule iinkonzo zethu kwaye sikwabonelele nge-CNC eyona ndlela ibalaseleyo kubathengi bethu

I-PRTCNC Factory iqhuba ukusuka kwiziko elinezindlu ezine ngokupheleleyo ze-diy cnc router ukwakha iiworkshops eziqinisekisa imveliso esebenzayo Ukongeza sinendawo yokugcina imigangatho emihlanu elungelelaniswe kakuhle kwaye ivulekileyo ukulungiselela uluhlu lwethu olukhulu Siyakwazi ukuqinisekisa ukuthunyelwa ngokukhawuleza kunye nokunciphisa ukulinda. ixesha lokuba abathengi bethu bafumane oomatshini be-CNC abakumgangatho ophezulu Ixesha lokuhanjiswa koomatshini abaqhelekileyo lidla ngokuba ziintsuku ezi-5-7 ngelixa oomatshini abakhiwe ngokusekelwe kwiinkcukacha zabathengi ngokuqhelekileyo zisiwe ngaphakathi kwe-15-30 yeentsuku zokusebenza