Have you ever taken a moment to wonder how amazing it is to make beautiful, captivating 3D designs? You probably thought how you once saw a duck, a superhero, or a perfect figure created out of neatly carved wood pieces or something in your favorite TV show. Brace yourself! These incredible designs happen to be made by pretty machines, under the name, 3D carving machine! Just think of these machines as if they were huge robots whose aim is to get hold of a pretty little block of stuff, wood or foam, and next change it into any object you can imagine. These machines get hold of a block, on a special computer program, a path is drawn, and there goes your innovative design on the computer system is done, hence your machine does 3D relief carving to function it out to life! The Unfathomable World of 3D Carving Throughout history, 3D carving has been in use for such a long time. Nevertheless, the price-electric machines that have the power to achieve much larger projects, with intricate details, in ways not previously unimaginable have only come up more recently. It allows artists to bring into being complex designs and concepts waste their time a few years’ years ago or that were impossible to act out due to manual work and tools. whereas one of the most notable features of 3D relief carving is the ability to be experimented on several materials, from wood to plastic, foam, and metal, the capabilities are beyond.. Hence artists can make sculptures, toys blanketing, and the mysteries of the universe..

Now, there are a lot of machines that can get you into most any size 3D carving job. From solid, industrial-strength machines to small desktop versions for the home, you can get one in stores. Later you can also make it yourself and start using the door though get one or find an accessible makerspace where this is provided The first step to creativity.

You see, when you get a 3D carving machine the whole world opens up. Thankfully, for those of you who might like to let the professionals take care of more creative tasks (and why not! If you are, in that case most common STL files can be found on thingslike Thingiverse and MyMiniFactory.

At the time of their release, 3D carving machines were only available to manufacture exact etchings and carvings that demanded a high standard. It truly excels itself when it comes to complex pieces, using a lot of lines and high amounts of detail which allow artists worldwide to do some fabulous work with little trouble.

For example, imagine that you were making a scale model car The 3D carving can also have the fine detail sculpted into it - there are headlights, grille pieces and wheels in this shot above. While doing this manually, and perfectly at scale would be a difficult task, the same thing can be achieved by 3D carving machines with significant precision.

Perhaps a bit surprisingly 3D carving machines can do so much more than they look like. This means that these machines can cut nearly any design you imagine, with the use of algorithms. Some prefer to utilize them for shaping distinct figures, while others leverage their capability of manufacturing custom parts required in machines or toys.

In one example, 3D carving machines were harnessed to create prosthetic limbs for amputees. These machines are used to make the virtual garment and they fit very snug, resulting in a design that conforms exactly to the body for which it was designed.

In other words, the world of 3D carving machine is an exciting one with endless possibilities. Brand new challenging roads to be a novice or professional trialblazer everyday. Who can say? Perhaps you have, what you think is the next life-changing 3D print design run up your sleeve!

Though 3D carving as a technique is thousands of years old, the introduction of powerful and affordable electrical machines to perform much larger projects using intricate detail in ways never before possible has recently become much more common. Now, artists have the ability to create complex designs and ideas that just a few years ago were impossible with good old manual work or typical tools.

One of the notable characteristics for 3D carving is its flexibility to be tried over an extensive list materials. From wood to plastic, foam or even metal the options are endless. Its versatility allows artists to make sculptures, toys blanketing and so many mysteries of the universe.

These days, there are an assortment of machines that will help get you set up with any number 3D carving project. From solid, industrial-strength machines to small desktop versions for the home, its there is a solution outthere. Render yourself one for personal use at home or find a local makerspace/workshop that offers this solution The door to creative expression is opened

When you attain a 3D carving machine, the whole world opens up for you. Fortunately, if you prefer to leave creativity in the hands of experienced designers (and why not!) then there are plenty of STL files available on platforms such as Thingiverse and MyMiniFactory.

When it was released, 3D carving machines were just offered to create fastidious etchings and carvings that required an impressive precision. They shine the most when it comes to intricate designs that require a high level of accuracy, helping artists around the world create some fantastic complex pieces with ease.

Imagine, for example, making a scale model of car. Beyond the fine detail - from headlights to grille and wheels - that can be machined into a 3D carving. Doing this with the kind of precision 3D carving machines enable, and at scale would be difficult manually but is a walk in the park for a machine.

Somewhat startingly, 3D carving machines are actually capable of much more than they might seem to be from conventions. Thanks to this, these machines are able to algorithmically carve almost any design you can think of. A few people use them to mold detailed figures, others exploit their capacity to make custom parts for machines or toys.

One recent application has seen 3D carving machines used to produce prosthetic limbs for amputees. They modify the virtual garment since these machines are skilled at precise fitting this provides a design that adapts perfectly to their body.

Simply put, the world of 3D carving machines is a thrilling place full of potential. Everyday there are new adventurous roads for you to be a beginner or trailblazing expert. Who can say? Maybe you have an idea for the next world-changing 3D print design!

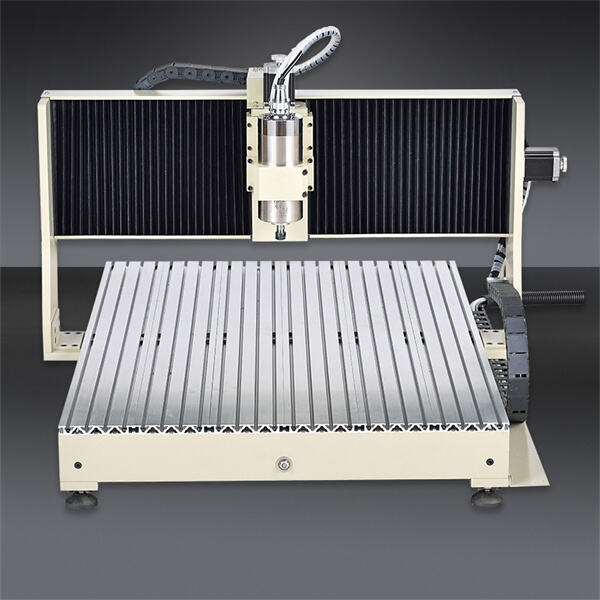

We adhere to strict and controlled quality assurance procedures. Our unique production method involves testing, installing, and then disassembling and packaging the CNC routers to ensure that the product is of top quality. From the choice of raw materials to the stages of production and testing We pay attention to the smallest of details. Additionally, we have a comprehensive after-sales system with 24 hour, no-cost technical assistance via email, Skype or 3d carving machine. TradeMessenger.

Foshan Puruite Technology Co., Ltd (PRTCNC Factory) is a prestigious ODM 3d carving machine manufacturer with a focus on CNC routers. We've been devoted to research, development production, sale and maintenance service of high-quality CNC routers since the year 2012 when we started our business. Our self-production and self-sales model does not just guarantee the supply of superior CNC routers but also helps customers save their budget.

We're a CNC router manufacturer that has experience that is extensive exporting services and products and making services custom-designed to meet diverse demands of our customers We understand that customers require specific specifications or work on a budget and we're focused on solutions that are providing meet what's needed of clients Our experience we can design machines that have excellent look and performance while working within 3d carving machine We make use of well-known CNC brands such as Sainsmart VEVOR and Yorahome These partnerships help us enhance our services and supply top-quality CNC routers to your customers

PRTCNC Factory is housed in a structure that has four fully-equipped workshops This guarantees an production that is 3d carving machine We have a big well-organized warehouse with five floors to store our big stock We can guarantee a fast delivery and minimize the waiting time for our clients getting high-quality CNC machines The delivery time for standard machines is generally 5-7 days while machines built according to specs provided by the consumer are generally speaking delivered in 15-30 days